How to Achieve Supply Chain Optimization with Pallet Racking Solutions

In today's fast-paced business environment, optimizing your supply chain is crucial for maintaining a competitive edge. With increasing demands and evolving market trends, organizations must streamline operations to reduce costs, improve efficiency, and enhance customer satisfaction. One of the most effective strategies for achieving supply chain optimization is leveraging pallet racking solutions. This blog post explores how pallet racking can significantly enhance your supply chain operations.

Understanding Pallet Racking Solutions

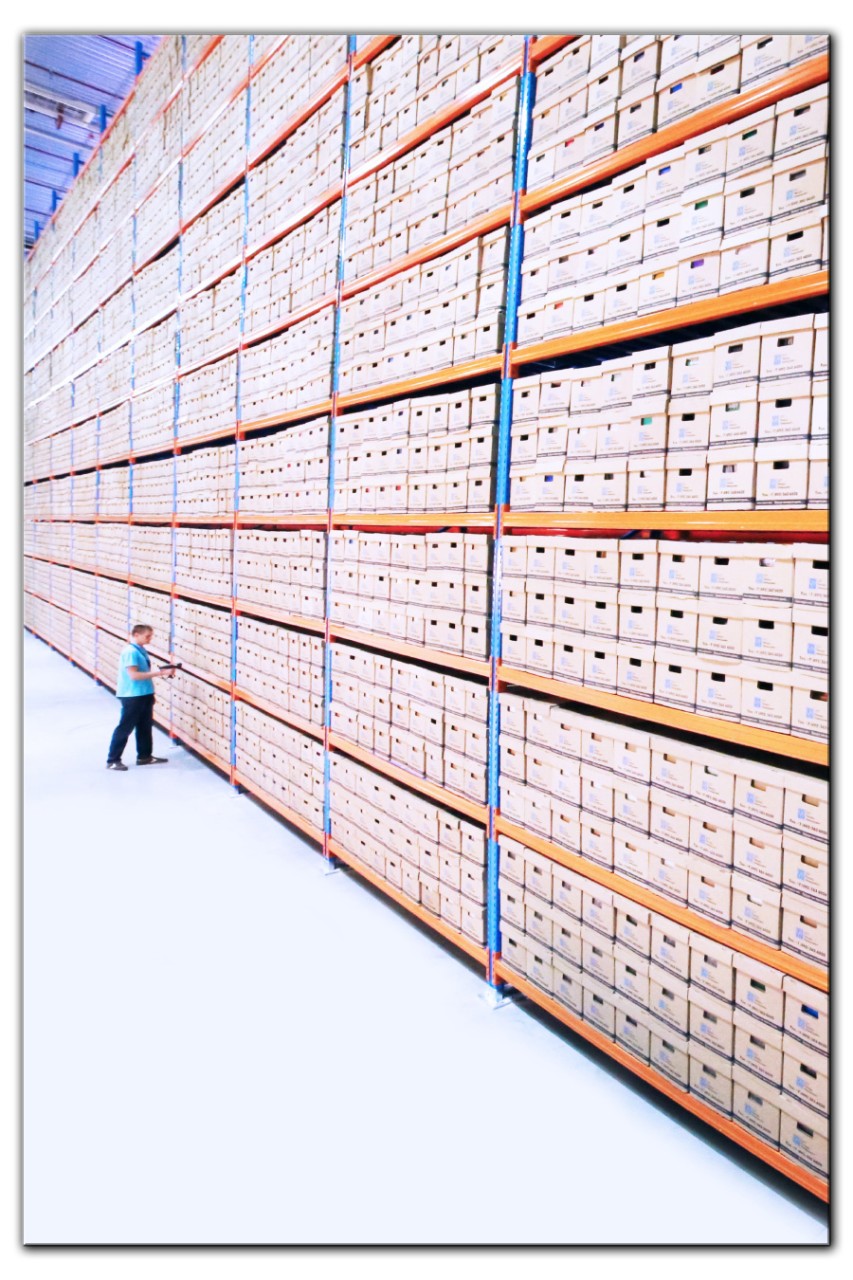

Pallet racking is a system that allows for the efficient storage of goods on pallets, using vertical space to optimize warehouse capacity. Various types of pallet racking systems exist, including selective racking, drive-in racking, push-back racking, and pallet flow racking. Each system has distinct advantages tailored to different operations, making it vital for businesses to choose the right one that aligns with their specific needs.

The Benefits of Pallet Racking for Supply Chain Optimization

- Maximized Storage Space

One of the primary advantages of pallet racking is the ability to maximize storage capacity. By utilizing vertical space, pallet racking systems can significantly increase the storage density of a warehouse. This optimized use of space means you can store more products in a smaller footprint, reducing real estate costs and allowing for better inventory management.

2. Improved Inventory Management

Effective inventory management is essential for optimizing the supply chain. Pallet racking allows for easy visibility and accessibility of goods. Systems like FIFO (First In, First Out) or LIFO (Last In, First Out) can be seamlessly employed with pallet flow racking, ensuring that products are rotated properly and minimizing the risk of obsolescence. This not only streamlines picking processes but also promotes accuracy and reduces stock discrepancies.

3. Enhanced Operational Efficiency

Efficient warehouse operations are directly tied to supply chain performance. With an organized pallet racking system, warehouse staff can easily locate and retrieve products, minimizing the time spent on picking and packing. This increased efficiency translates into faster order fulfilment and a better overall customer experience.

4. Flexibility and Scalability

Businesses often experience fluctuations in demand. Pallet racking systems can be designed for flexibility and scalability, allowing warehouses to adjust storage solutions as needs change. Whether your business is expanding or experiencing seasonal spikes, adaptable racking systems can accommodate varying inventory levels without extensive reconfiguration.

5. Reduced Labor Costs

By streamlining the storage and retrieval processes, pallet racking can help reduce labour costs. With efficient systems in place, employees can complete tasks more quickly and with less effort, thereby reducing the number of labour hours required to manage inventory. This efficiency also enhances employee morale, as workers can accomplish their tasks swiftly.

6. Enhanced Safety and Compliance

Safety is a top priority in warehouse operations. Pallet racking systems can be designed with safety features that comply with regulatory requirements. Properly organized and maintained racking reduces the risk of accidents, ensuring the safety of your workforce and minimizing liability costs.

Choosing the Right Pallet Racking System

When considering pallet racking solutions for supply chain optimization, it's crucial to assess your specific needs. Here are a few key factors to consider:

Warehouse Layout: The design of your warehouse can influence the effectiveness of your pallet racking solution. Consider aisle width, accessibility, and flow of goods when selecting a system.

Future Growth: Choose a racking system that is easily expandable to accommodate business growth or changes in inventory patterns.

Budget: While it's essential to invest in quality racking solutions, ensure they align with your budget and provide long-term return on investment.

For Pallet Racking Solutions that improve your supply chain management and optimisation, contact our professional team today.

Comments